- NCP series controllable pitch propeller

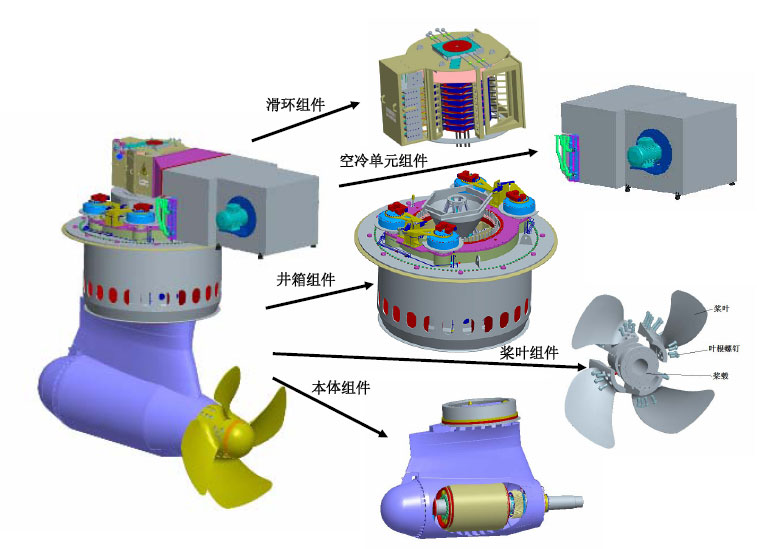

- NRP series azimuth thruster (FP/CP)

- Other configurations of azimuth thruster

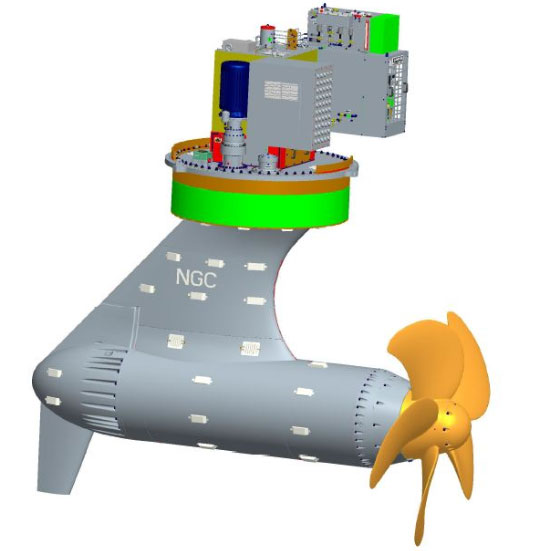

- NEPod series electrical propulsion system

- NFT/NCT series tunnel thruster

- NFP series shaft/rudder system

- NRV series rotary vane steering gear

- CK series controllable pitch propeller gearbox

- CG series fixed pitch propeller gearbox

- Jacking Gears

- Dredger gearbox

- NHF/NHC series hydraulic coupling

- FP series FI-FI brochure gearbox

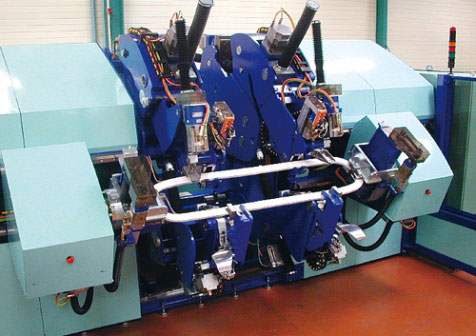

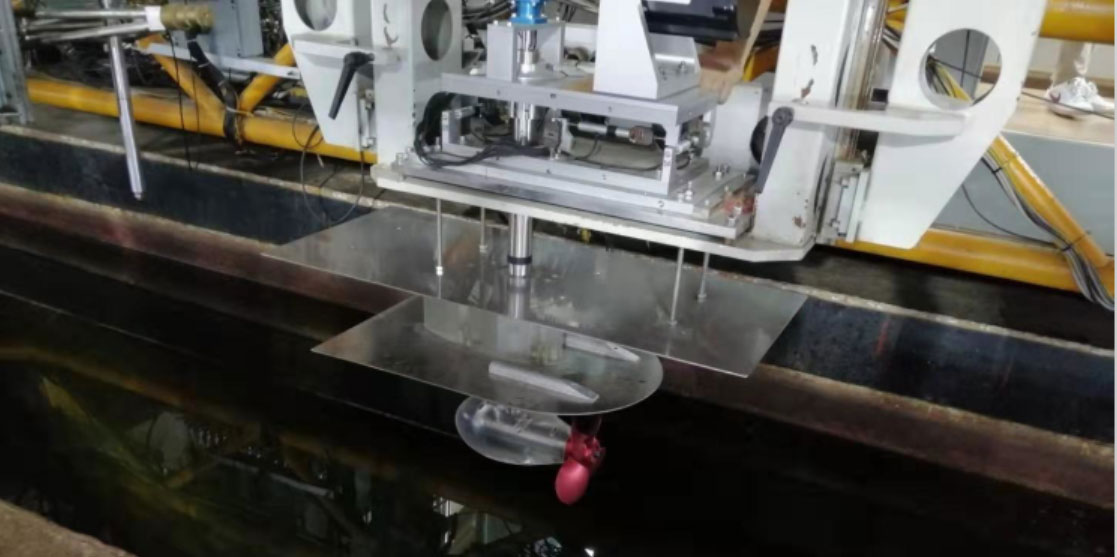

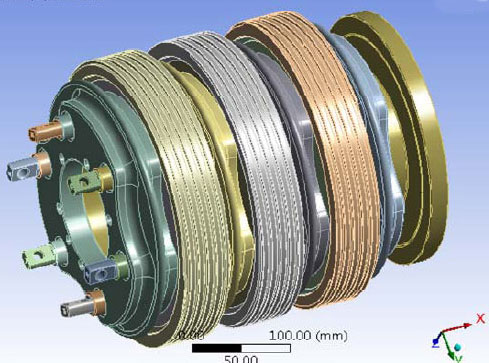

As a scientific and technological innovation-oriented high-tech enterprise, Nanjing High Accurate Marine Equipment Co. , Ltd. summarizes the design and manufacturing of mechanical azimuth thruster and on the basis of hundreds of real ship data, breaks through the compatibility research of polar ship pod propulsion device, overall design research of pod propulsion device, reliability design technology research on pod propulsion device, the technical research on the design of high-torque anti-overload pod propulsion motor and drive device, the research on the hydrodynamic and load characteristics of the pod propulsion device and the experimental verification technology of the pod propulsion device successively, has developed the NEPod series of pod-type electric propulsor. We have published 9 papers and more than 40 patents, of which 21 are invention patents, and 15 patents have been granted, 12 thematic studies were formed. Taking the permanent magnet pod propulsor of international leading level as benchmark, the motor efficiency completedŌēź97.5%, insulation class H-class, temperature rise <80K, rudder accuracy Ōēż┬▒ 1 degree. The prototype design, manufacture and class certification work of 5MW permanent magnet pod with polar ice class PC3, is appraised by provincial accreditation committee the independent development of the largest domestic specifications pod-type electric propulsion system, the overall technology is in the leading position of domestic market and same level of international market. NGC Marine has built a mature pod propulsion development industry chain in China, is capable to deliver 20 sets of independent brand NEPod series below 10MW per year, including the design, high-precision manufacturing and testing.

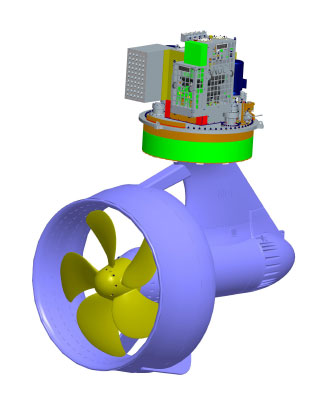

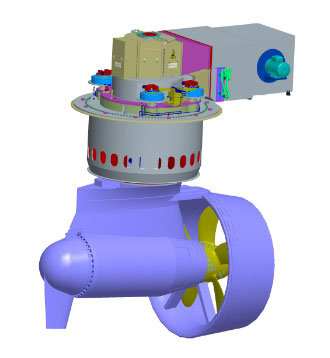

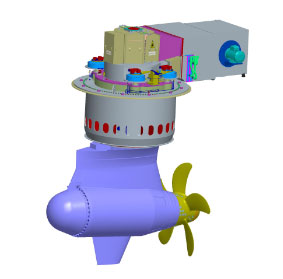

Based on its success and rich experience in mechanical azimuth thruster, NGC Marine has developed NEPod series permanent magnetic electrical pod propulsion by moving the electric motor down into underwater housing so as to omit the gear parts and with the motor driving the propeller directly.

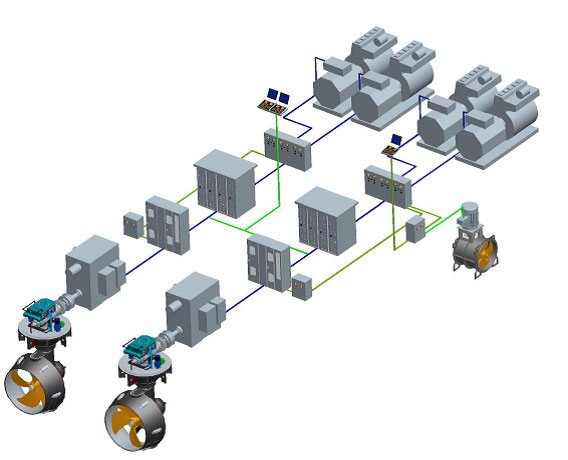

Layout of mechanical azimuth thruster system in engine room Layout of pod electrical propulsion system in engine room

Advantages of pod electrical propulsion compared to traditional mechanical azimuth thruster:

1.Convenient for structural layout of the vessel; demanding less space in engine room; highly flexible for ship design, construction and operation.

2.Improving and optimizing wake field of hull and propulsion system, thus to get better hydrodynamic efficiency;

3.By removing the mechanical shafting and gearing parts, unnecessary mechanical efficiency loss of 3% could be avoided; consequently vibration and noise of thruster can be reduced significantly and then to reach design requirements for grade 1 of modern cruise ship comfort level;

4.Efficiency of PM Motor with big length to diameter ratio can be up to 97% or higher by sea water direct cooling or with air cooling as an additional cooling method.

5.Performance of NEPod in high ice class region is much better than traditional azimuth thruster. Effective energy saving of pod propulsion can be up to 10% compared to traditional azimuth thrusters.

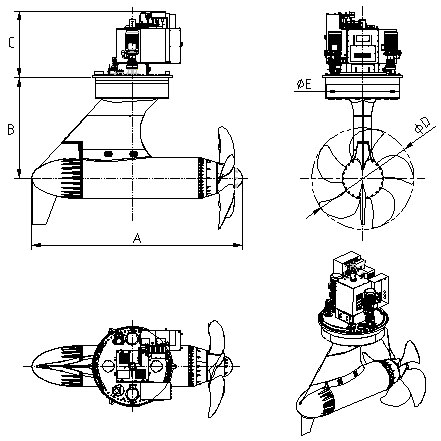

|

Model |

Power (Kw) |

Max.Propeller speed (rpm) |

Propeller dia. D(mm) |

A (mm) |

B (mm) |

C (mm) |

E (mm) |

|

150-220 |

700 |

900~1200 |

1700 |

930 |

890 |

520 | |

|

NEPod510 |

200-315 |

700 |

1000-1300 |

1800 |

930 |

900 |

550 |

|

NEPod590 |

300-400 |

630 |

1000~1400 |

2000 |

1100 |

900 |

650 |

|

NEPod670 |

355-630 |

560 |

1200~1600 |

2400 |

1250 |

1000 |

800 |

|

NEPod760 |

560-1000 |

420 |

1500~2100 |

2700 |

1400 |

1000 |

1100 |

|

NEPod850 |

900~1400 |

360 |

2000~2500 |

3840 |

1950 |

2300 |

1800 |

|

NEPod960 |

1300~2000 |

320 |

2400~3000 |

4800 |

2445 |

2300 |

2200 |

|

NEPod1200 |

1800~3350 |

260 |

3000~3500 |

5730 |

3300 |

2300 |

2400 |

|

NEPod1400 |

3150~5000 |

230 |

3400~4000 |

6800 |

3500 |

2300 |

2520 |

|

NEPod1600 |

4500~7500 |

220 |

4000~4500 |

9000 |

5000 |

2600 |

5050 |

|

NEPod1800 |

7000~10000 |

210 |

4200~4500 |

9400 |

5400 |

2900 |

6000 |

Maximum permissible angle range a & b: 6

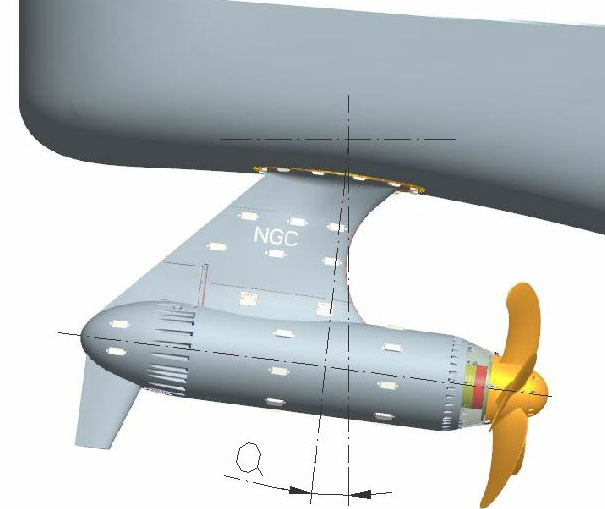

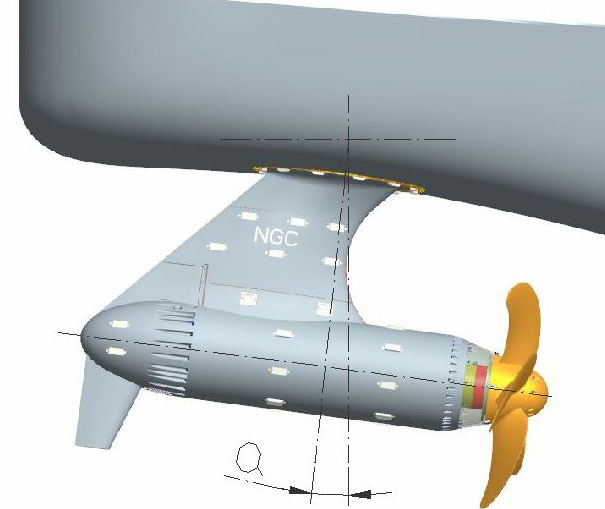

By considering specific overall requirements of different types of vessels, NGC Marine proposes the most suitable NEPod type, i.e. Nozzle type, high steering type or Contra-rotating type to improve the propulsion efficiency and maneuverability.

Nozzle type High steering type Contra-rotating type

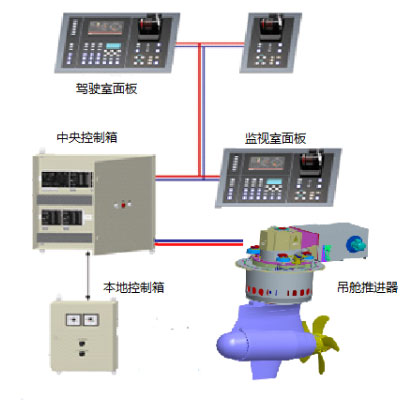

NEPod6000 remote control system is full follow-up propulsion control system based on PLC controls. Steering control and motor speed control can be realized by a joint control handle at the bridge. Turning the handle horizontally would control steering of NEPod in 360┬░; Push and pull the handle forward and backward would control the motor speed. When there is failure in follow-up control, rapid switch to backup control system or to local control of steering and speed is available.

Main functions

1.Speed control of main motor

2.Control of rudder angle

3.Load control of main motor

4.Monitoring of sliding ring signal

5.Monitoring and alarming

Control mode

1.Follow-up control by handle(rudder angle/speed)

2.Non-follow up control by button (rudder angle/speed)

3.DP/JOY mode

4.Auto pilot mode

5.Joint control mode

System interface

1.DP interface

2.JOYSTICK interface

3.VDR interface

4.Auto pilot interface

5.Integrated alarm interface

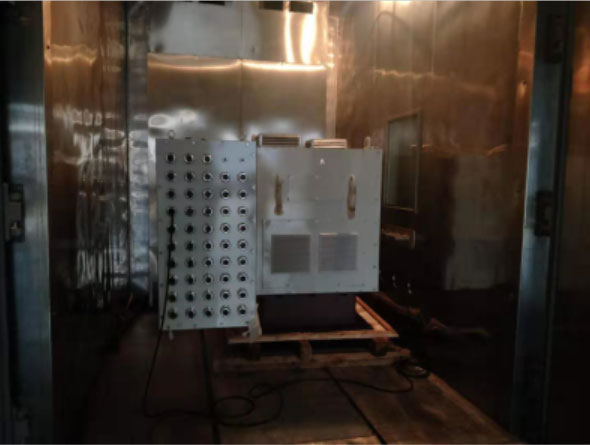

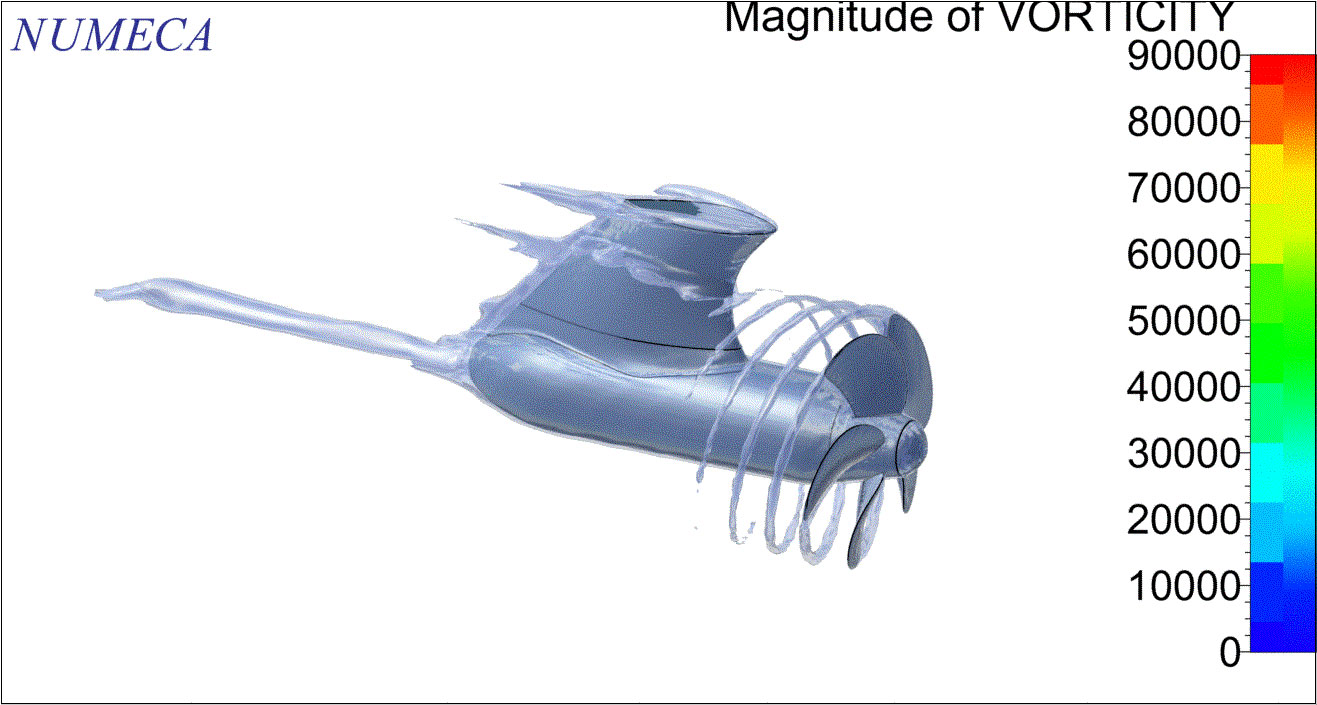

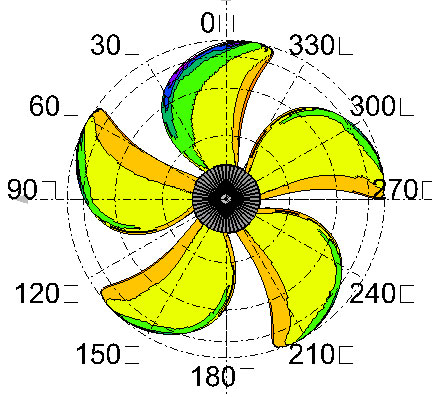

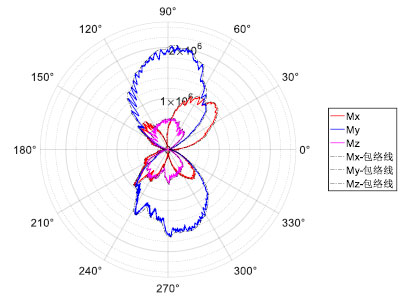

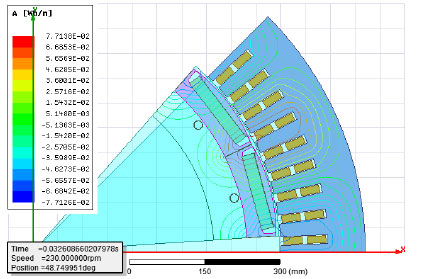

Advanced hydrodynamic calculation and testing methods

3-D product design and simulation

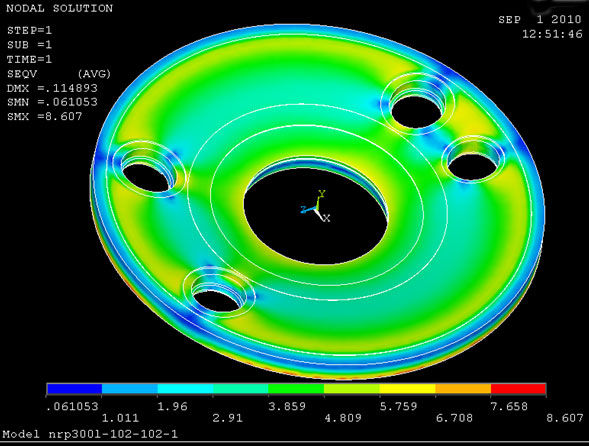

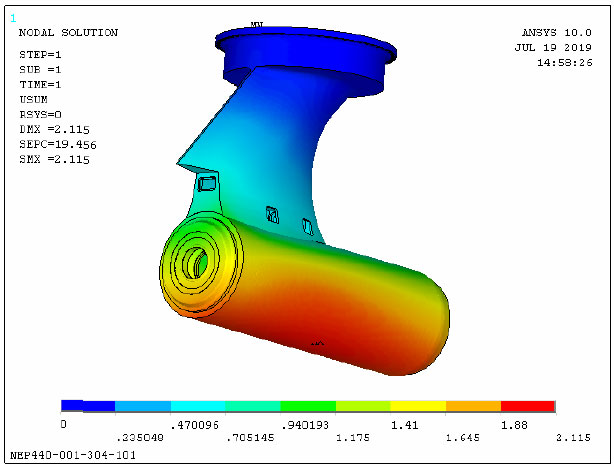

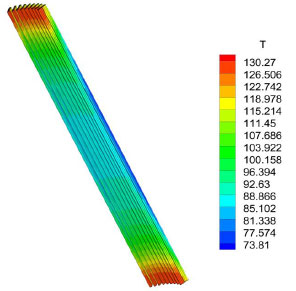

CAE finite element analysis

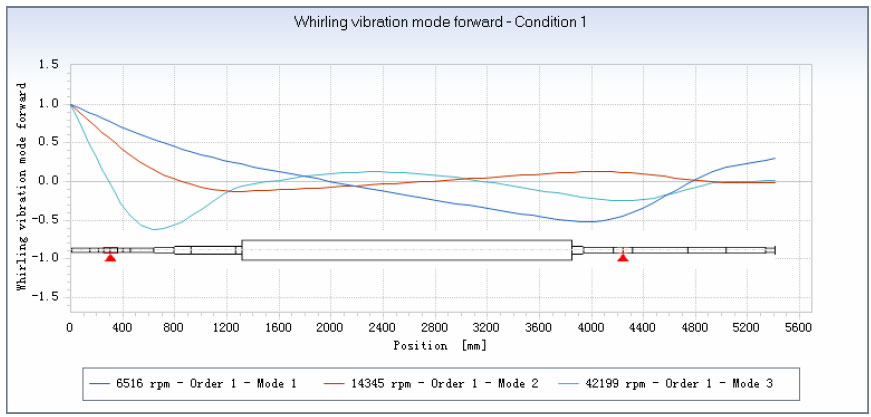

Shafting whirling vibration calculation with DNV software